LUMASENSE Announces the new PULSAR 4 for Condition Based Monitoring of Petrochemical Combustion Vessels, ThermalSpection CVM for Critical Vessel Monitoring

and

IGAR6 Advanced Pyrometer

(Please scroll completely down this page for details!!)

“The PULSAR 4 is the best way to keep valuable petrochemical assets performing and prevent unwarranted downtime”

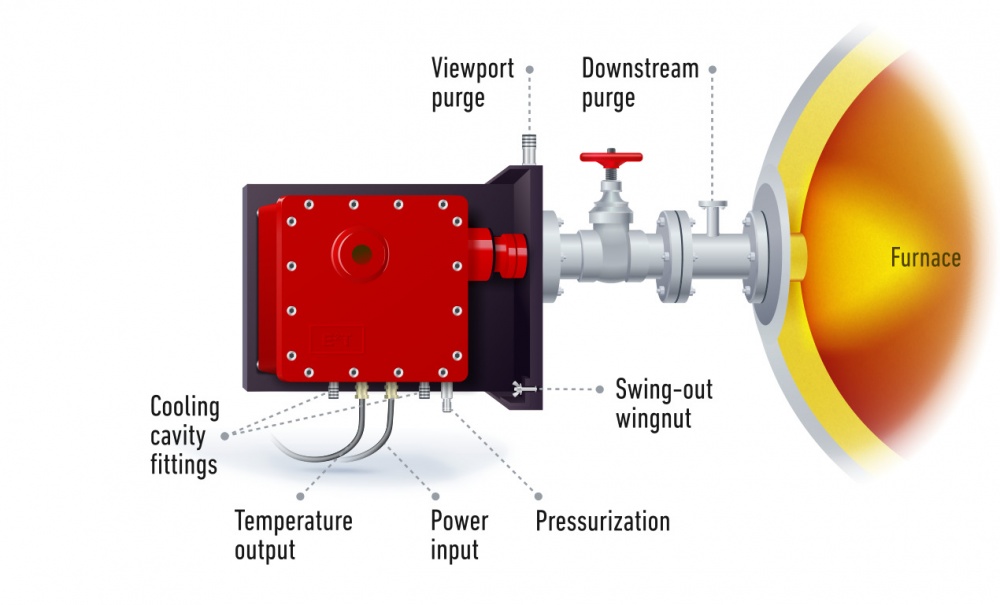

Oil & Gas operations are heavily dependent on combustion based processes to supply the world’s growing energy needs. The PULSAR 4 is intended for monitoring the Refractory and Gas temperatures inside Sulfur Recovery Units, Sulfur Burners, and Thermal Oxidizer Furnaces frequently found at petrochemical facilities.

“Any one of these vessels can force a shut down that will cost $1M or more per day”, says LumaSense CEO, Steve Abely. “Unplanned downtime eats into planned profits, whereas increasing uptime increases profit. The PULSAR 4 is a condition based maintenance system to protect refinery profits”, continues Abely.

The PULSAR 4 is an explosion proof infrared thermometer (pyrometer) with the ability to see through flames and simultaneously deliver the Refractory Temperature and Gas Temperature with precision to 0.3 °C and a range of 350° to 2000° C. The PULSAR 4 Advanced features LumaSense’s proprietary Smart Flame Measurement Algorithm (Smart FMA™) which accounts for flame transparency that can affect the temperature readings for a more precise view of activity inside these vessels. LumaSense’s updated and powerful InfraWin software interprets the data from the PULSAR 4 for analysis inside the control room.

“Our Smart FMA™ technology, serviceability, and long standing relationships with major producers is what separates the PULSAR 4 from the rest”, says E2T product manager David Ducharme.

Customers with existing PULSAR II and III systems can leverage their existing infrastructure to upgrade these units to the new PULSAR 4 and its advanced capabilities.

CHECK OUT THESE OTHER SOLUTIONS FROM Lumasense

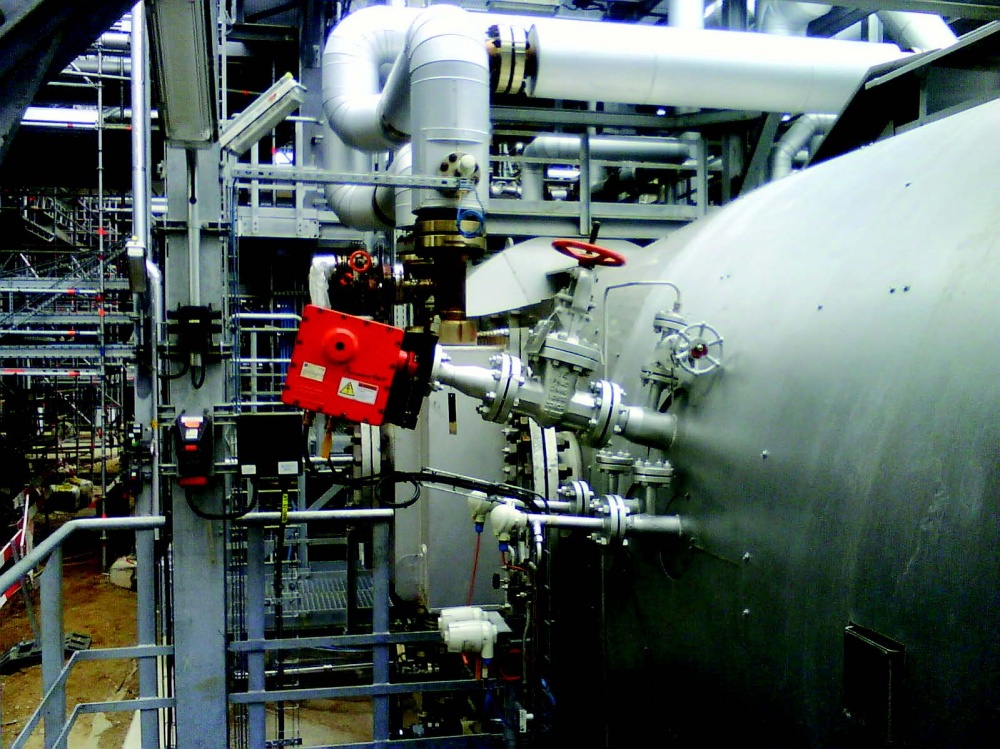

The ThermalSpection™ Critical Vessel Monitoring system is a turn-key solution for monitoring critical vessels, such as gasifier skin temperature.

Critical vessels in the chemicals, refining and power industries operate at high temperature and pressure and are at risk of failure as joints and refractory degrade. The consequences of undetected failures can be very serious. The ThermalSpection CVM system uses non-contact thermal imaging to provide real-time, continuous, automated fault detection and monitoring for your most critical assets.

Features include

Early fault detection to reduce risk, emergencies and unplanned outages

Continuous, automated monitoring

Easy integration into existing plant DCS and data historian

Designed for hazardous area installations (ATEX, Class I Div 2)

Auto “Hot Spot” Tracking Feature

HTML visualization displays for broadcast on plant intranet

Data Historian archive

OPC/Modbus interface

Optional integration with OSIsoft’s PI database system

Stationary, digital ratio pyrometer with possible combination of 1-color and 2-color measurement for non-contact temperature measurements in ranges between 100 and 2000 °C

Key Features

Wide temperature ranges and various operating modes:

1-color mode: 100 ... 2000 °C

2-color mode: 250 ... 2000 °C

Smart mode: 100 ... 2000 °C

automatic (temperature-dependent) transition from 1-color to 2-color mode

“Dirty Window” Warning

Fully digital core for sub-ranging and adopted analog output

Very fast 2 ms response time for highly dynamic processes

Best optics in its class with manual focus capability

4 digit LED display

Robust, stainless steel sensor for harsh environments (IP65/NEMA4)